Product Series

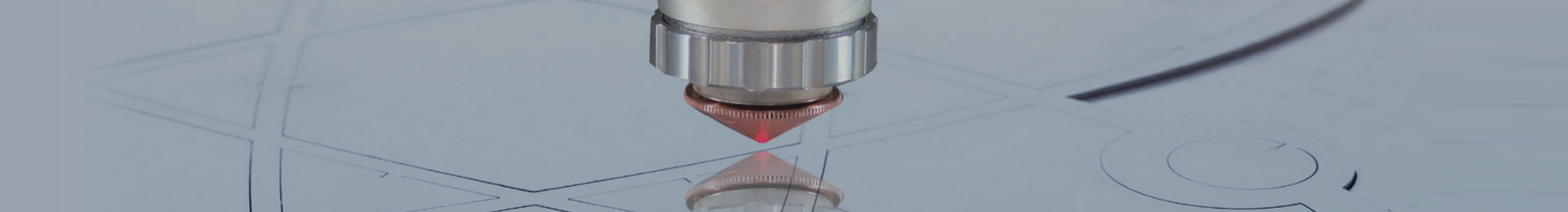

3D Five-Axis Laser Cutting System

Product Features

Stability: High-rigid, diagonal-pull cantilever structure or gantry structure ensures long-term high-speed, high-precision and stable cutting

Safety: Machine tool safety protection meets CE international safety standards.

Diversification: Positioner and moving worktable, etc. can be used for loading and unloading, wide application

Cost performance: Low cost investment, low use and maintenance cost

Product Features

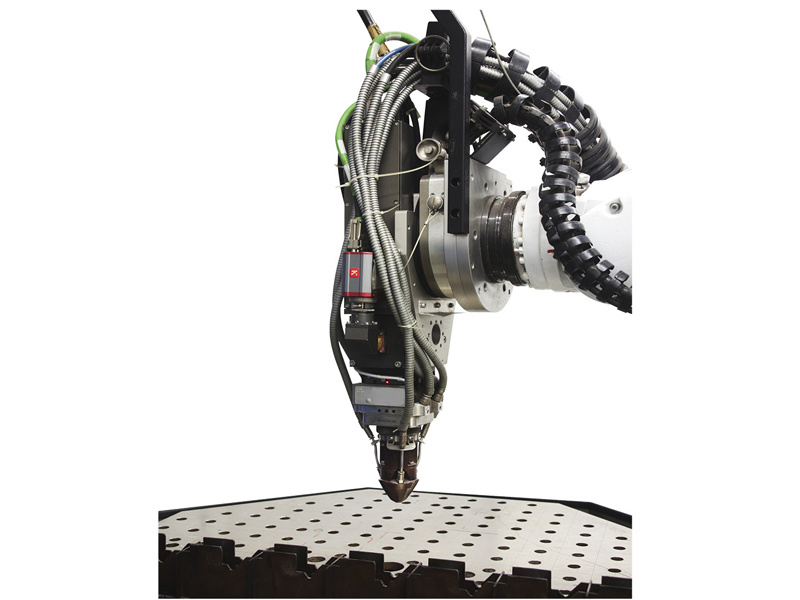

Combination of industrial robot and fiber laser

Multi-robot combination

Fastcut algorithm achieves faster speed without reducing the original cutting accuracy of the robot

TCP is automatically calibrated, detected and corrected to ensure stable and reliable performance

The function of expert database ensures better cutting quality

3D Robot Non-Metal Laser Cutting System

Product Features

High Precision: STAUBLI five-axis robot hat high repositioning accuracy and ensures cutting precision of workpieces

Advanced technology: built-in light guide design for robot arm with the technology of internal optical path design and whole optical path debugging

Energy-saving and efficient: low maintenance cost for the internal reflection system of beam, making the whole system more simplified

Application process: mature cutting process database to meet 3D cutting of metal, non-metal and composite materials

Non-destructive processing: laser flexible processing is non-contact, small deformation of material processing and no damage on the surface

Flexible configuration: optional positioner, multiple robots combinations to improve cutting efficiency or complex parts processing

Safety protection: optional protection room and dust removal system

Laser Combined Processing System

Product Features

System equipped with band robot + laser generator, laser generator can realize multi-path fiber output

Can be equipped with ordinary fiber welding head, 3D scanning mirror welding head, laser cladding head, laser quenching head, to meet the customized needs

With automatic quick change function of multi-group laser processing head, fast response to different typed of customer laser processing, easy to operate

Modular design, can be integrated into a variety of different types of laser processing solutions

Can be divided into single-function equipment

Can be taught by offline software programming, also can be taught manually, convenient and fast

Access to different types of laser processing expert database

Option of robot additional axis and positioner with different functions, which can achieve the linkage with robot and expand processing range and extend processing function

Product Features

The function of expert database ensures better welding quality

System mainly equipped with brand manipulator + laser generator + welding head

Six-axis robot combined with flexible transmission of fiber laser can easily complete 3D part welding

Stable running of equipment, high automation level, good compatibility

Low cost of single-piece processing, suitable for all kinds of mass production

Options of different welding methods such as self-fusion welding, wire filling welding, remote welding, arc composite welding, braze welding etc.

Options of rotary table and positioner to realize switching of different workpiece processing

Turbocharger Laser Welding System

Product Features

Applied for the welding of O type ring and rocker arm; automatic assembly , testing and laser welding after manual feeding

Takt time: 30 seconds per piece, with a capacity of 600,000 pieces per year

The equipment is divided into six stations.

3D Robot Laser Quenching System

Product Features

Fast laser quenching speed, small heat affected area, no deformation of parts

The control of quenching area can realize the processing of special workpieces with difficulty for traditional method

Quenching hardness is higher than the conventional method, fine quenching microstructure and good strength and toughness

Quick heating and cooling, using the workpiece matrix to realize “self-quenching”

After light beam shaping to get a square spot, processing efficiency is high; can select slide rail for robot to broaden processing range

3D Robot Laser Cladding System

Product Features

System mainly equipped with brand manipulator + laser generator + cladding head + powder feeder

Six-axis robot combined with flexible transmission of fiber laser can easily complete 3D part cladding

The system can combine the offline software programming to quickly complete a variety of curved surface or irregular shaped parts of the processing program teaching

High efficiency, little deformation

Fast cooling speed, easy to get fine crystal compact structure

Cladding layer has low dilution and can form strong metallurgical structure with good mechanical properties

Customer service hotline: 4007702600 Sales Tel: 086-510-68576047 Administrative Tel: 086-510-68556000 After-sales Tel: 086-510-68576045

Fax: 086-510-81001279 E-mail: sales1.wx@yawei.cc Address: No. 1 Minshan Road, Xinwu District, Wuxi City, Jiangsu Province, China

Mobile Website

Copyright: Jaingsu Yawei Chuangkeyuan Laser Equipment Co., Ltd.