Predict the Future Factory, Let Gree Fall in Love with Yawei Intelligent Manufacturing

Published:

2022-11-28

“Predicting the Future Factory, Let Gree Fall in Love with Yawei Intelligent Manufacturing” through the combination of software and hardware to help Changsha Gree comprehensively improve the manufacturing execution ability of the factory, improve the management of the production site of the enterprise, furthermore supporting the strategic goal of “Industry 4.0” of Gree Group!

Changsha Gree HVAC Equipment Co., Ltd. is the tenth air conditioning base of Zhuhai Gree for the global deployment, with a total investment of 5 billion yuan, officially put into operation at the end of 2018, is a comprehensive production base of Gree household air conditioners and commercial air conditioners. The product market share covers central, southwest and northwest China, filling the gap of home appliance industry in Hunan Province. The factory is planned to build a “Green Factory, Intelligent Factory” as its goal, the whole project adopts a large number of international leading intelligent equipment as well as the equipment developed independently by Gree, with an industrial superiority in terms of process automation level, production efficiency, energy conservation and environmental protection, etc.

Focusing on the needs of Changsha Gree to build an intelligent sheet metal factory, the sales and technical teams of Yawei Machine Tool made all efforts to conduct careful workpiece analysis and capacity planning, and provided intelligent sheet metal factory solutions including uncoiled flying shear line, punching and shearing composite line, three-dimensional warehouse as hardware support and integrated control of production management system. Each processing unit can be operated automatically by the central computer in “online mode” to realize the automatic production of full line from raw materials to stamping, shearing and stacking; Each processing unit can also operate independently in "offline mode", and separately linked with the warehouse unit to realize the automatic batch cycle processing of different workpieces. The overall project has been officially handed over to Changsha Gree factory in July 2019, after several months of operation, the efficient use of processing equipment has been realized, the production capacity has been fully improved, and the intelligent production management mode has set up the basic structure of the future unmanned factory.

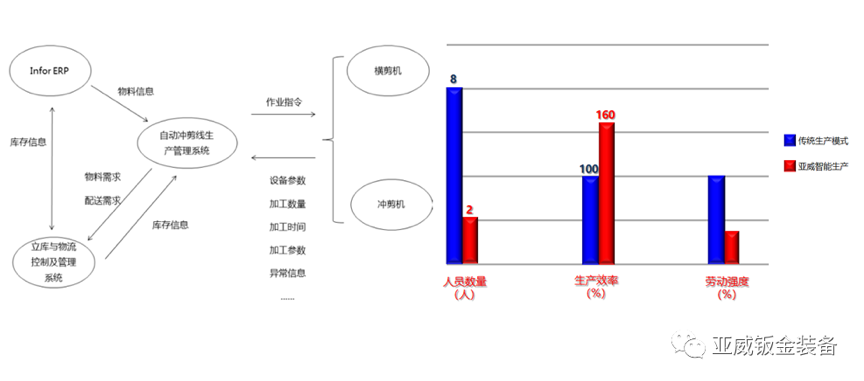

As the "central brain" of the entire production line, Yawei production management system (MES) has interconnection with software and hardware such as InforERP, warehouse and logistics control and management system (WMS), flying shearing line, punching and cutting line to achieve collaborative and efficient operation. Compared with the traditional operation mode of single machine processing with manual transfer, the number of employees has been reduced from 8 to 2. Due to the tome reduction of loading and unloading as well as warehousing logistics, the comprehensive productivity has increased by more than 60%, and the work intensity of employees has also been greatly reduced. Gree employees only need to input batch command for products every day, and the whole set of equipment can complete the production tasks from steel coils to various finished parts. Especially, the effect of Yawei MES production management system to improve production efficiency is more obvious when responding to customers' multi-variety, small-batch production needs. Meanwhile, the MES production management system can also integrate management functions such as production scheduling, product tracking, quality control, equipment failure analysis, network reports on the unified platform, and use a unified database and network connection to provide workshop management information services for production departments, quality inspection departments, process departments and logistics departments.

“Predicting the Future Factory, Let Gree Fall in Love with Yawei Intelligent Manufacturing” through the combination of software and hardware to help Changsha Gree comprehensively improve the manufacturing execution ability of the factory, improve the management of the production site of the enterprise, furthermore supporting the strategic goal of “Industry 4.0” of Gree Group!

Customer service hotline: 4007702600 Sales Tel: 086-510-68576047 Administrative Tel: 086-510-68556000 After-sales Tel: 086-510-68576045

Fax: 086-510-81001279 E-mail: sales1.wx@yawei.cc Address: No. 1 Minshan Road, Xinwu District, Wuxi City, Jiangsu Province, China

Mobile Website

Copyright: Jaingsu Yawei Chuangkeyuan Laser Equipment Co., Ltd.